Contact Us

or call us now 800.268.5620

or call us now 800.268.5620

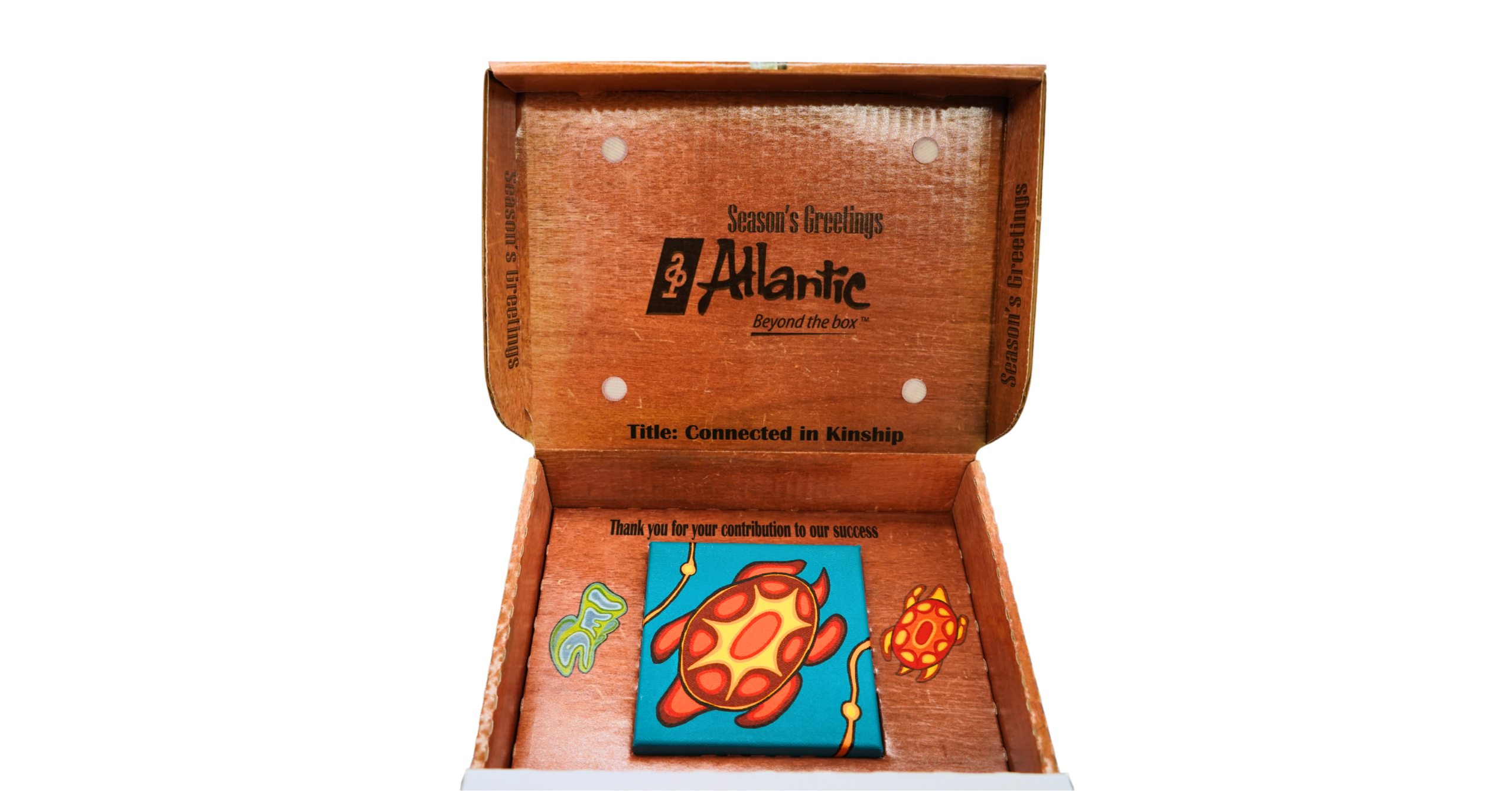

In our interview with Phil Watson, Design Manager, Atlantic Packaging Products we spoke about how corrugated packaging design is a dynamic, evolving field. Success depends on a collaborative approach, transparent communication, and the courage to push creative boundaries while honoring practical realities. Looking ahead, the integration of sustainable materials, smart technology, and inventive structural design will continue to elevate the standard for what corrugated packaging can achieve.

Phil Watson (Phil): Several leading trends define corrugated packaging design today. Customers increasingly expect cost savings, speed to market, and high adaptability for e-commerce. Minimizing waste and simplifying supply chains are also central themes, driven in part by the need to operate efficiently at a scale. Digital printing technology is surging in popularity, enabling high-quality graphics and flexibility across order sizes without the traditional costs associated with printing plates.

Atlantic’s design management team regularly collaborates with clients to not only meet these expectations but exceed them, building partnerships rooted in understanding unique packaging challenges. By conducting packaging audits, we standardize style, size, and materials to drive down costs while keeping quality and performance high.

Phil: Sustainability isn’t just a trend; it’s becoming an industry standard. Over the past four decades, we’ve seen a remarkable shift from skepticism about recycled materials to a near-universal demand for environmentally friendly solutions. The increased awareness, fueled by media coverage and evolving regulations, means design teams now treat sustainability as a foundational requirement.

We prioritize the replacement or elimination of less sustainable materials, such as plastics or foams, whenever possible. Our ongoing challenge is to design packaging solutions that are recyclable, reusable, and stand out without sacrificing performance. These efforts align both with customer expectations and our collective responsibility as stewards of the environment.

Phil: Innovations in digital printing are fundamentally changing the landscape. State-of-the-art digital presses allow us to offer high-impact graphics at volumes that range from small runs to large-scale orders, without the need for costly print plates. This technology gives brands the ability to adapt rapidly to market shifts, seasonal promotions, or personalized packaging campaigns.

Beyond traditional branding, packaging now often serves as a bridge to digital experiences. Features like QR codes and augmented reality elements are becoming commonplace, enabling smart packaging that interacts with consumer’s post-purchase.

Our print teams work closely with structural designers to ensure that the outer graphics not only reflect brand identity but also integrate seamlessly with the underlying functional design of the box.

Phil: Creativity and functionality are not competing priorities; they work best in tandem. Our approach starts with asking the right questions about a product’s supply chain, handling, and end-use requirements. We sit down with clients to review their full SKU sets and identify opportunities for standardization and cost reduction, but always through a creative lens.

We engage in brainstorming sessions and conduct site observations to see where packaging can be improved operationally. For example, our work with pizza chains led to the invention of improved locking mechanisms and special inserts to maintain product quality. Another example, when we designed a triangular beer packaging as a promotional pack—a solution that effectively captured customer attention and earned industry recognition. These examples illustrate our enduring commitment to balancing innovation with practical concerns.

You know what I love about corrugated packaging? It’s such a durable and versatile material. Fascinatingly, it dates back to historical times as one of the earliest forms of packaging. Not only does it offer incredible efficiency and flexibility, but it also shines as a sustainable choice. Truly remarkable.

– Phil Watson, Design Manager, Atlantic Packaging Products

Phil: Inspiration often starts with the team. Many of our designers come from diverse creative backgrounds, including art and photography. We foster a culture where passion and curiosity are as valued as technical skills. Regular exposure to industry publications, international design awards, and ongoing collaboration with both suppliers and customers keeps us sharp.

Building relationships with clients encourages us to push boundaries and find bespoke solutions for their business goals. Through internal and external brainstorming, we test ideas and learn from successful (and occasionally less successful) prototypes. Recognition from our peers, such as industry awards, is gratifying, but real satisfaction comes from solving problems that matter to our customers.

Phil: Customers today are more informed and more demanding than at any point in the past. They value transparency, rapid turnaround times, and packaging that aligns with their brand’s purpose. They also expect their packaging partners to be proactive in recommending innovations or cost-saving measures.

Our practice of offering internal packaging audits demonstrates this shift; customers now see us as collaborators, not just suppliers. The trend toward e-commerce and smart packaging solutions is also driving innovation in areas like tamper-proofing, serial tracking, and QR code imaging to enable richer consumer engagement.

By continuously soliciting feedback from our partners, we refine our processes and ensure that every new package aligns with the evolving needs of the marketplace.

Phil: Absolutely. Structural innovation is where much of today’s packaging excitement lies. We’re seeing increased demand for designs that are both clever and resource efficient. For example, our team’s proprietary locking mechanisms for pizza boxes and optimized board inserts enable better product quality and substantial material savings for our clients.

We also experiment with unique forms for specialty promotions, such as our award-winning triangular beer carton packaging solution that I have already mentioned about. While some of these innovations are specific to short-term campaigns, many structural advances lead to permanent improvements in production efficiency and product protection across industries.

The future will likely see more packaging designed with secondary uses in mind, enhanced compatibility with automation, and stronger integration of innovative technologies.

Our ongoing commitment is to combine practical functionality with true innovation, ensuring that each solution brings measurable value to both our customers and the environment.

© 2026 Atlantic Packaging Products Ltd. All rights reserved.

Atlantic Packaging Products

We firmly believe that the internet should be available and accessible to anyone, and are committed to providing a website that is accessible to the widest possible audience, regardless of circumstance and ability.

To fulfill this, we aim to adhere as strictly as possible to the World Wide Web Consortium’s (W3C) Web Content Accessibility Guidelines 2.1 (WCAG 2.1) at the AA level. These guidelines explain how to make web content accessible to people with a wide array of disabilities. Complying with those guidelines helps us ensure that the website is accessible to all people: blind people, people with motor impairments, visual impairment, cognitive disabilities, and more.

This website utilizes various technologies that are meant to make it as accessible as possible at all times. We utilize an accessibility interface that allows persons with specific disabilities to adjust the website’s UI (user interface) and design it to their personal needs.

Additionally, the website utilizes an AI-based application that runs in the background and optimizes its accessibility level constantly. This application remediates the website’s HTML, adapts Its functionality and behavior for screen-readers used by the blind users, and for keyboard functions used by individuals with motor impairments.

If you’ve found a malfunction or have ideas for improvement, we’ll be happy to hear from you. You can reach out to the website’s operators by using the following email

Our website implements the ARIA attributes (Accessible Rich Internet Applications) technique, alongside various different behavioral changes, to ensure blind users visiting with screen-readers are able to read, comprehend, and enjoy the website’s functions. As soon as a user with a screen-reader enters your site, they immediately receive a prompt to enter the Screen-Reader Profile so they can browse and operate your site effectively. Here’s how our website covers some of the most important screen-reader requirements, alongside console screenshots of code examples:

Screen-reader optimization: we run a background process that learns the website’s components from top to bottom, to ensure ongoing compliance even when updating the website. In this process, we provide screen-readers with meaningful data using the ARIA set of attributes. For example, we provide accurate form labels; descriptions for actionable icons (social media icons, search icons, cart icons, etc.); validation guidance for form inputs; element roles such as buttons, menus, modal dialogues (popups), and others. Additionally, the background process scans all the website’s images and provides an accurate and meaningful image-object-recognition-based description as an ALT (alternate text) tag for images that are not described. It will also extract texts that are embedded within the image, using an OCR (optical character recognition) technology. To turn on screen-reader adjustments at any time, users need only to press the Alt+1 keyboard combination. Screen-reader users also get automatic announcements to turn the Screen-reader mode on as soon as they enter the website.

These adjustments are compatible with all popular screen readers, including JAWS and NVDA.

Keyboard navigation optimization: The background process also adjusts the website’s HTML, and adds various behaviors using JavaScript code to make the website operable by the keyboard. This includes the ability to navigate the website using the Tab and Shift+Tab keys, operate dropdowns with the arrow keys, close them with Esc, trigger buttons and links using the Enter key, navigate between radio and checkbox elements using the arrow keys, and fill them in with the Spacebar or Enter key.Additionally, keyboard users will find quick-navigation and content-skip menus, available at any time by clicking Alt+1, or as the first elements of the site while navigating with the keyboard. The background process also handles triggered popups by moving the keyboard focus towards them as soon as they appear, and not allow the focus drift outside it.

Users can also use shortcuts such as “M” (menus), “H” (headings), “F” (forms), “B” (buttons), and “G” (graphics) to jump to specific elements.

We aim to support the widest array of browsers and assistive technologies as possible, so our users can choose the best fitting tools for them, with as few limitations as possible. Therefore, we have worked very hard to be able to support all major systems that comprise over 95% of the user market share including Google Chrome, Mozilla Firefox, Apple Safari, Opera and Microsoft Edge, JAWS and NVDA (screen readers).

Despite our very best efforts to allow anybody to adjust the website to their needs. There may still be pages or sections that are not fully accessible, are in the process of becoming accessible, or are lacking an adequate technological solution to make them accessible. Still, we are continually improving our accessibility, adding, updating and improving its options and features, and developing and adopting new technologies. All this is meant to reach the optimal level of accessibility, following technological advancements. For any assistance, please reach out to

We use cookies to enhance your browsing and personalize content. By continuing to use this website, you agree to our use of cookies as outlined in our Privacy Policy.